Viscosity class of engine oil

Basic and commonly used engine oil specification. Do you know what this term actually means?

To determine the viscosity class, four parameters must be determined. The first is the structural viscosity of the oil at low temperatures (CCS). This is a test that determines the engine's ability to start at low temperatures. The second parameter is the pumpability of the oil determined using a minirotational viscometer (MRV). The oil temperature is lowered for the time needed to crystallize aliphatic hydrocarbons, which form a gel in the oil that can prevent the oil from flowing into the pump. This simulates the conditions in the initial phase of engine operation at low winter temperatures, when the oil is not warmed up. The above parameters are responsible for the "winter" (marked with the letter "W") oil viscosity class. The next two are tested at high temperatures and enable the determination of the "summer" class. One of them is kinematic viscosity at 100°C, a simple test performed by many laboratories, which involves measuring the rate of oil flow under the influence of gravity in a viscometer. This test simulates a situation in which oil flows into the oil pan. The latest study involves measuring dynamic viscosity under high temperature, high shear (HTHS) conditions. The measurement is made at a temperature of 150°C. This test best reflects real conditions during engine operation. This is an extremely important parameter. Too low an HTHS viscosity will not ensure adequate oil film thickness, which may lead to boundary friction and, consequently, to rapid wear and even engine failure, while too high an HTHS result results in high internal oil friction, which affects engine performance and fuel consumption. Reducing the HTHS viscosity of many new classes of engine oils in recent years has made it possible to meet the fuel consumption and exhaust emission requirements set by international environmental protection agreements.

It is worth noting that the edition of the SAE J300 specification (2015-01) presented below contains new viscosity classes, i.e. 8 and 12. Their formulation and inclusion in the scope of the specification is due to intensive work on improving lubrication technology by scientists from Japan who strive to reduce internal friction liquid (oil), and therefore a decrease in fuel consumption and exhaust emissions. While current knowledge in the field of rheology allows the creation of lubricants of this viscosity class, we must wait a few more years for development in the automotive industry, and more specifically in engine design, that will allow their widespread use.

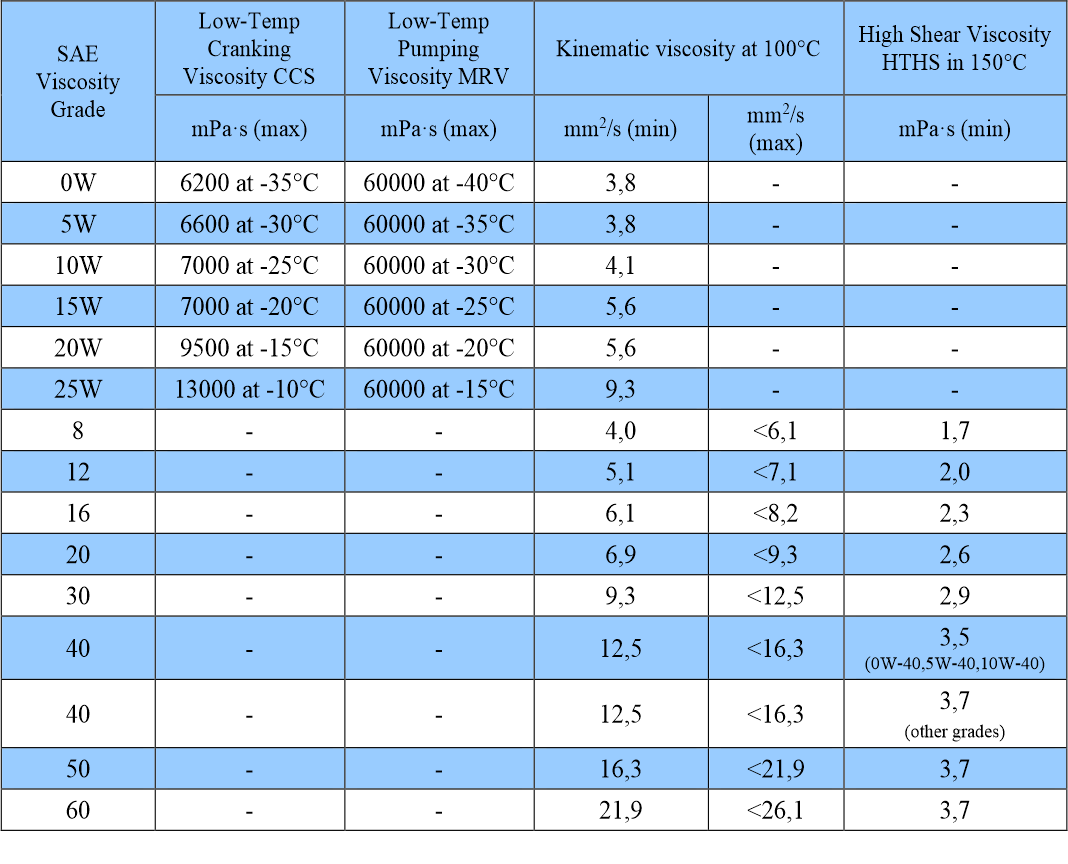

The table below shows the requirements of SAE J300 (2015-01) for the four parameters described above for the currently applicable viscosity grades

In order for an oil to meet a specific viscosity class, it is necessary to meet the requirements for all tests. Meeting each of them individually is necessary but not sufficient to determine the viscosity class. Moreover, the parameters in the standard are critical and therefore must be strictly met. This means that to confirm the viscosity class, it is not enough for each parameter to be within the limits given above, but the measurement error must also be taken into account. This approach implies the need to formulate the oil in such a way that the parameters of the twenty-fold test meet the requirements of the standard with each repetition, or leave at least a 5% margin of error in the case of a smaller number of test repetitions..

Michał Świątek

Bibliography:

[1] E. Wright, The impact of SAE Critical Specifications to the formulating and manufacture of automotive oils, “Lube Magazine” 2017 (December), No. 142, p. 33-37.

[2] A. Stone, New low viscosity grade engine oil specification rises from the ashes of category development delays, “Fuels and Lubes Magazine” 2017 (May), Volume 23, Issue 2, p. 18-21.